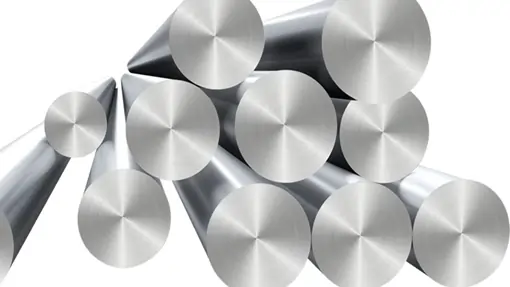

Precision machining plays a crucial role in manufacturing, ensuring that components meet exact specifications for industries like aerospace, automotive, and medical devices. Among the various materials used in precision machining, high-quality steel round bars stand out for their strength, durability, and versatility. These bars form the foundation for manufacturing essential machine parts, ensuring reliability and longevity. Forte Precision Metals, Inc., based in Franklin Park, Illinois, specializes in providing high-quality steel round bars tailored for precision machining applications.

Why High-Quality Steel Round Bars Matter in Precision Machining

The quality of materials used in machining directly impacts the performance of the final product. High-quality steel round bars provide superior machinability, allowing for smooth cuts and precise dimensions. This results in parts that fit seamlessly into machinery, reducing wear and tear over time. Using substandard materials can lead to increased production errors, higher rejection rates, and compromised durability, making it essential to source steel from trusted suppliers like Forte Precision Metals, Inc.

Material Composition and Strength

One of the key reasons high-quality steel round bars are preferred for machining is their exceptional strength and composition. These bars come in various steel grades, including stainless steel, carbon steel, and alloy steel, each suited for specific applications. Stainless steel round bars, for example, offer excellent corrosion resistance, making them ideal for environments exposed to moisture and chemicals. Carbon steel bars provide high tensile strength, while alloy steel bars offer enhanced toughness and wear resistance, ensuring longevity in heavy-duty applications.

Improved Machinability for Precision Cuts

Machining efficiency depends on how well the material responds to cutting, milling, and turning processes. High-quality steel round bars are manufactured with a focus on consistent hardness and uniform grain structure, allowing machinists to achieve precise cuts with minimal tool wear. This results in better surface finishes and reduces the need for additional processing steps. Forte Precision Metals, Inc. ensures that its steel bars undergo rigorous quality checks to guarantee optimal machinability.

Centerless Grinding for Perfect Roundness

Centerless grinding is a crucial step in preparing steel round bars for machining. This process ensures that the bars have a uniform diameter and superior surface finish, eliminating imperfections that could affect performance. Centerless grinding enhances dimensional accuracy, which is critical for applications requiring tight tolerances. Forte Precision Metals, Inc. specializes in centerless grinding services, delivering steel round bars with exceptional roundness and straightness.

Chamfering for Precision and Safety

Chamfering is another essential service that enhances the usability of steel round bars. By creating bevelled edges, chamfering reduces the risk of sharp corners causing injuries or damaging machinery. It also facilitates smoother assembly and welding processes. Forte Precision Metals, Inc. offers professional chamfering services to ensure that steel round bars meet the highest safety and usability standards.

Custom Machining for Industry-Specific Needs

Different industries require steel bars with unique specifications. Custom machining services allow manufacturers to tailor steel round bars to precise dimensions and shapes. Whether for intricate aerospace components or robust automotive parts, Forte Precision Metals, Inc. provides custom machining solutions that align with industry standards and customer requirements.

Material Packaging and Handling

Proper packaging is crucial in maintaining the quality of steel round bars during transportation and storage. Without adequate protection, steel bars can develop rust, scratches, or deformities, compromising their usability. Forte Precision Metals, Inc. ensures that its steel products are packaged securely, preventing damage and maintaining their pristine condition upon delivery.

Metal Turning for Enhanced Performance

Metal turning is a fundamental machining process that shapes steel round bars into precise cylindrical components. This technique is widely used in producing shafts, bolts, and fasteners. With advanced turning capabilities, Forte Precision Metals, Inc. ensures high precision and consistency in all turned metal components, meeting stringent industry standards.

Milling and Polishing for Superior Surface Finish

Milling allows for the creation of complex geometries, while polishing enhances the surface quality of steel round bars. These processes are essential in applications where aesthetics and smooth finishes are crucial, such as in medical instruments or architectural components. Forte Precision Metals, Inc. offers expert milling and polishing services to ensure that every steel bar meets the highest quality standards.

Precision Metal Cutting for Accurate Dimensions

Accurate cutting is essential for ensuring that steel round bars fit perfectly into their intended applications. Forte Precision Metals, Inc. utilizes advanced cutting techniques to achieve precise lengths and reduce material wastage. Precision metal cutting services guarantee that customers receive steel bars tailored to their exact project specifications.

Steel Straightening for Optimal Performance

Warped or bent steel bars can cause significant issues in machining and final assembly. Steel straightening services correct any deviations, ensuring that bars maintain their intended shape and functionality. Forte Precision Metals, Inc. provides professional straightening solutions, delivering steel bars with impeccable alignment and accuracy.

Conclusion

High-quality steel round bars are the backbone of precision machining services, offering strength, durability, and exceptional machinability. From centerless grinding and chamfering to custom machining and material packaging, each process plays a vital role in ensuring that steel round bars meet the highest industry standards. Forte Precision Metals, Inc., located in Franklin Park, Illinois, stands as a trusted provider of premium steel products and machining services, supporting industries with reliable and expertly crafted solutions.

FAQs

Why are high-quality steel round bars important in precision machining?

High-quality steel round bars ensure precise cuts, durability, and superior machinability, reducing errors and improving the performance of machined components.

What types of steel round bars are best for machining?

Stainless steel bars offer corrosion resistance, carbon steel provides high strength, and alloy steel ensures enhanced wear resistance, making them ideal for various machining applications.

How does centerless grinding improve steel round bars?

Centerless grinding ensures uniform diameter, superior surface finish, and enhanced dimensional accuracy, making the bars ideal for precision machining.

What is the benefit of chamfering steel round bars?

Chamfering removes sharp edges, improving safety, ease of assembly, and welding compatibility while enhancing the overall usability of steel bars.

How does Forte Precision Metals, Inc. ensure high-quality steel round bars?

Forte Precision Metals, Inc. follows stringent quality control measures, including centerless grinding, custom machining, and precision cutting, to deliver top-tier steel products for industrial applications.